Brakes India Private Limited, a TVS group company, established in the year 1962 at Chennai as a joint venture between TVS and Lucas Industries, UK (100% subsidiary of ZF-TRW).

Now Brakes India Private Limited is the country’s largest producer of braking equipment for both automotive and non-automotive applications having its units in Chennai, Nanjangud, Sholinghur, Polambakkam & Gurgaon and marketing locations all over the country.

The factory is located in the temple town of Nanjangud which has two divisions namely Seal Division and Polymer Division.

Seal Division is an earmarked division for manufacture and supply of precision components made of rubber. These components technically called as seals, fits into Master cylinders, Wheel cylinders, Clutch cylinders, PCRVs and Servos of the hydraulic braking system of automobiles. The type of seals starts from a simple cup seal and ranges to gland type, special valve seals, PCRV seals, valve seats, recuperation seals, back seals and various types of ring seals. Caliper Seales are being exported to ZF-TRW, America.

Polymer Division is an earmarked division for manufacture and supply of wide and comprehensive range of high quality Engineering Thermoplastic developed specifically for the production of high performance injection moulded articles used in automotive, electrical, electronics, mechanical and high precision engineering industries.

Polymer Division is located on a picturesque sloping landscape overlooking the river Kapila, in the Industrial area of Nanjangud, located in Mysore dist. Karnataka. The sloping terrain was ideally suited for process flow.

Polymer Division manufactures a wide and comprehensive range of high quality engineering thermoplastics developed specifically for the production of high performance injection molded articles used in Automotive, Electrical, Electronics, Mechanical and high precision Engineering Industries. The Company aims at satisfying today's increasingly stringent market requirements for functional performance, reliability and consistently high quality.

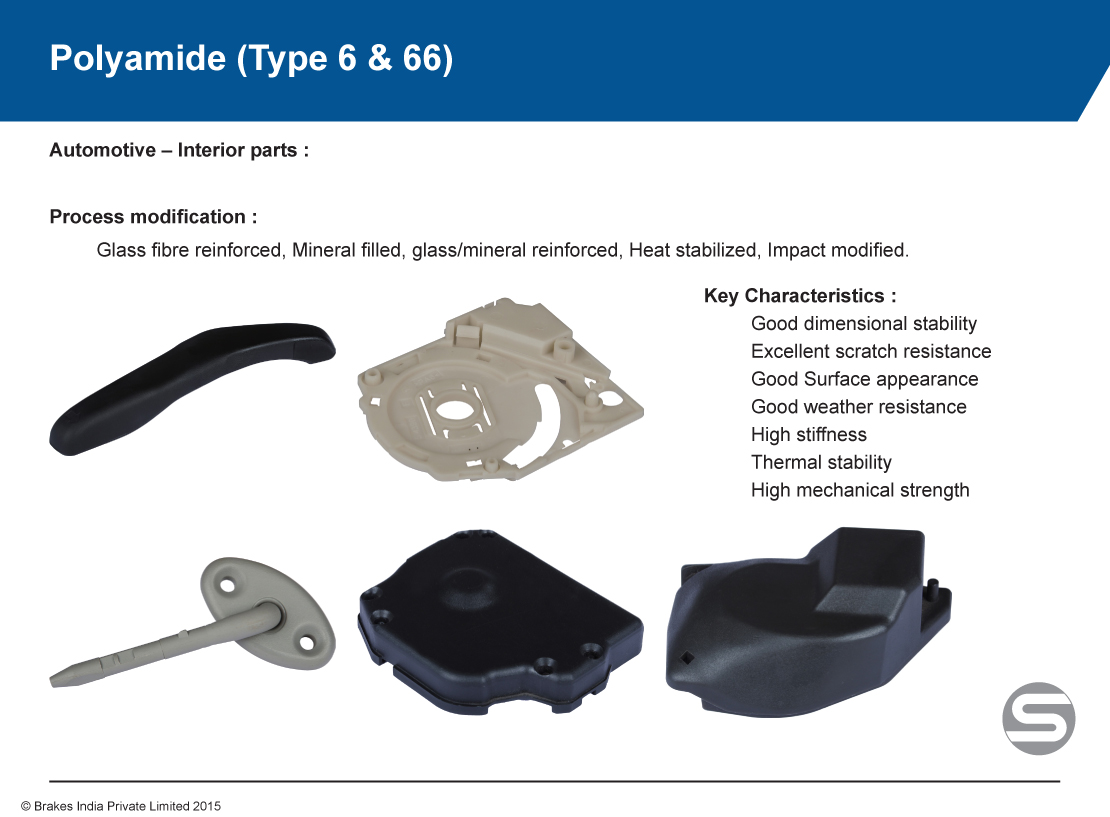

The Company's principal grades are derived from the basic thermoplastic resins such as Polypropylene, Polyamides, all of which serve the injection molding Industry. These products offer a combination of characteristics such as low specific weight, outstanding resilience at low temperatures, stiffness, creep resistance, heat deflection temperatures, dimensional stability and resistance to fatigue.

To ensure high product quality, the technical characteristics of the raw materials and the products are monitored by the Quality Assurance department. All tests are carried out in accordance with International standards. Color is assessed both by colorimetric methods and visually against a standard.

Quality Assurance does not end once the product leaves the plant. Polymer Division offers its customers assistance in the development of new products, Technical Support in processing, devising specifications and test methods and computer aided part design and control.

Polymer Division is accredited ISO 9001:2004 Quality Management System , ISO 14001:2004 Environment Management System. The Division has also been awarded for TPM Excellence first category.