Laizhou Kaifa thermal insulation material Co., Ltd. is located in Laizhou, Bohai, Weifang, Qingdao and Yantai in the East, 180 kilometers from Qingdao port, and convenient transportation. The company focuses on product quality and development of new products, as well as customer service experience. The introduction of advanced production equipment and technology ensures the stability of product quality. China's top class static steam curing, dynamic synthesis technology of plate, shell, arc and amorphous materials.

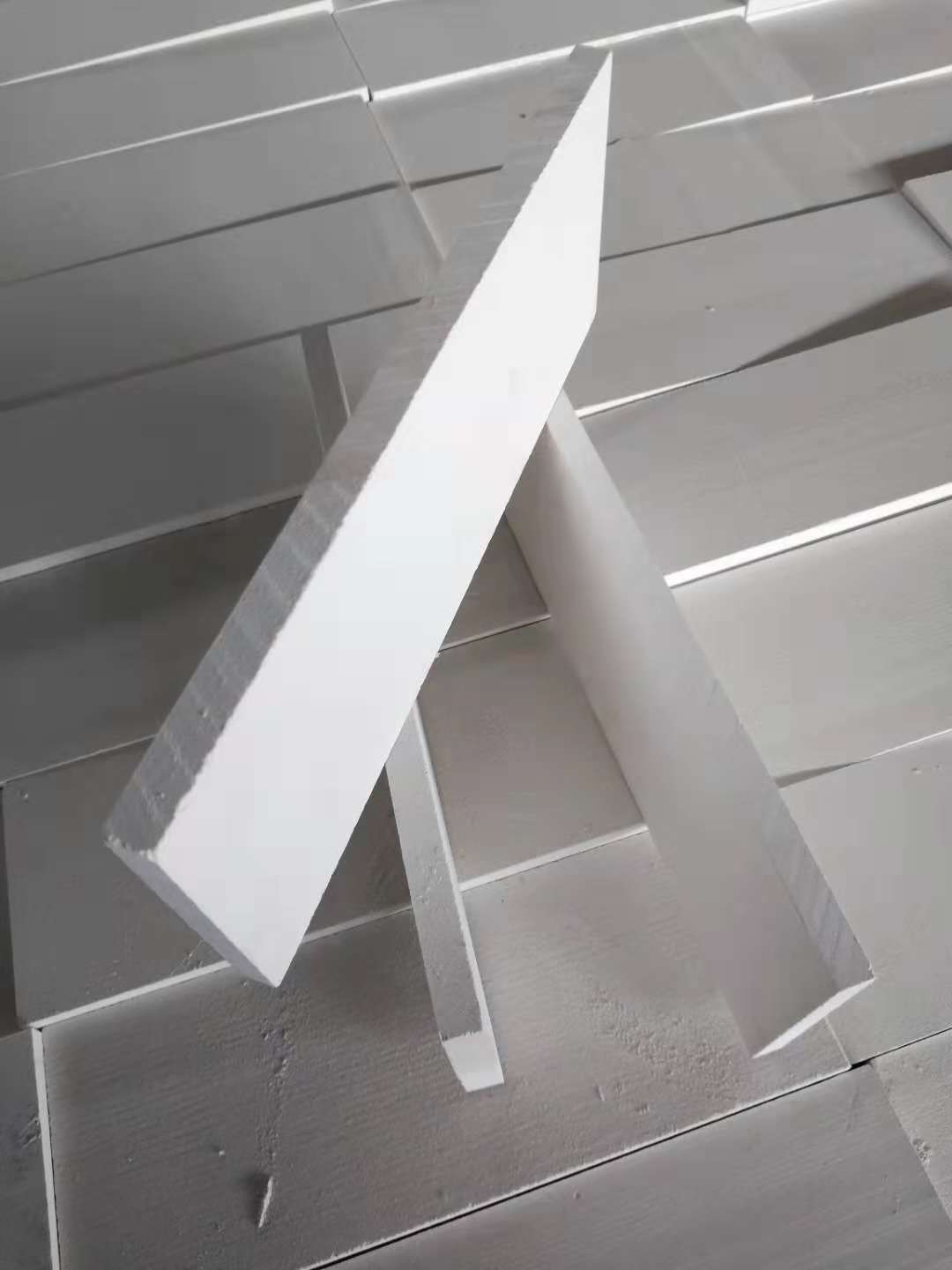

The main products of the company are 1050 degrees (1000 degrees) and 650 degrees of high temperature resistant calcium silicate board heat insulation products, HCS-20 high temperature calcium silicate waterproof board and supporting material BP-1 high temperature adhesive powder, high temperature resistant calcium silicate board special waterproof agent, calcium silicate insulation coating, the annual output of 20 thousand cubic. The company will provide high quality and high performance products for China and the world to contribute to energy conservation and fire safety.

High temperature calcium silicate products are widely used in the construction of urban heat network and the heat insulation of various kinds of kiln and pipeline in metallurgy, petroleum, chemical, cement, electronics, machinery, ceramics, glass, natural gas and other industries.

The main products of the company are 1050 degrees (1000 degrees) and 650 degrees of high temperature resistant calcium silicate board heat insulation products, HCS-20 high temperature calcium silicate waterproof board and supporting material BP-1 high temperature adhesive powder, high temperature resistant calcium silicate board special waterproof agent, calcium silicate insulation coating, the annual output of 20 thousand cubic. The company will provide high quality and high performance products for China and the world to contribute to energy conservation and fire safety.

High temperature calcium silicate products are widely used in the construction of urban heat network and the heat insulation of various kinds of kiln and pipeline in metallurgy, petroleum, chemical, cement, electronics, machinery, ceramics, glass, natural gas and other industries.